Piston Air Compressors

Our Reciprocating Air Compressors have low RPM design with quick, easy maintenance and renewable components. Easy access to the components allows for routine maintenance and replacement of parts like the individually cast cylinders, piston wear-sleeves and the 15,000-hour bearings.

Why Comptech Piston Air Compressor?

____

Fully air cooled design

____

Vibration free quieter operation

____

Designed for hot indian climate

____

Service friendly design

____

Low rpm, longer life

____

Lowest oil carry over

____

Sustainable design for decades

____

Lowest life cycle cost

Specification

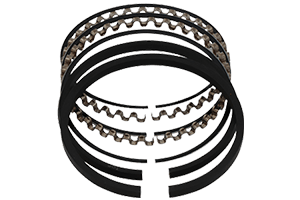

Piston Ring

Highly Efficient imported Piston Rings made with high grade material.

Benefits: Lowest Oil Carryover & better life.

Cylinder

Cylinders are bored with super precision & finished by a special process.

Benefits: Minimum oil consumption and negligible wear for great durability.

Valves

Concentric ring type valves with imported stainless steel material.

Benefits: Higher Efficiency and longer life.

Crank Case & CranK Shaft

Strong and robust Crank Case and shaft is made of High grade cast iron which goes through complete hardening process.

Benefits: Better life & Low Downtime.

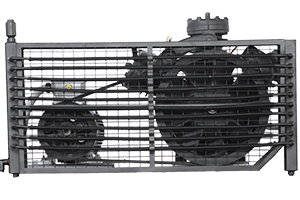

Air Cooled After Cooler

Based on the Hot Climate of India, we provide Big size, high efficient Air & Oil Cooler which increases the durability of the Compressor.

Benefits: Better Cooling & better compressor life.

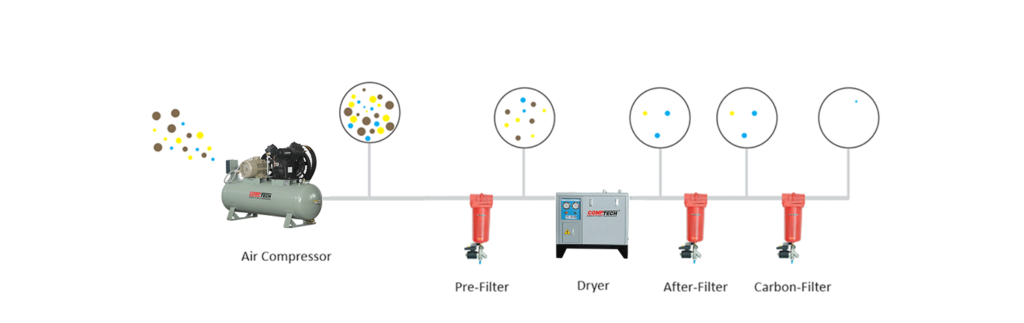

Typical Air Supply System

Air boosters take pre-compressed air from an existing network (your plant air system) or from a low-pressure compressor and increase it to the required higher pressure. A CompTech Air Booster is a specially designed reciprocating compressor that accepts elevated inlet pressures of 10 kg/cm² and boosts that pressure up as far as 40 kg/cm².